KONNEXIO's team of industry experts will guide you, from inquiry to delivery, through every aspect of your project.

Our team of experienced machine designers can guide you through the most important decisions about your assembly project. They will carefully analyze your product to ensure its suitability for automation, determine what degree of automation is appropriate, and make recommendations concerning the product design, process and capability of the proposed automation, quality checks, and any other causative factors.

When it is common for product updates to occur mid-stream, customers can be confident that projects will remain on schedule with the help of our experienced project managers.

Each task is planned carefully, allowing for contingencies and routine follow-up is carried out to ensure optimal results. Regular progress reports are made; the depth of detail and frequency determined by the customer.

Since an integral part of an automation project is the programming logic and hardware, our controls technologists adhere to the highest standards when designing the electrical schematics and performing the programming. We use major brands such as Omron and Siemens but can integrate whatever a customer’s preference might be. Further, we ensure that training is provided along with after installation support.

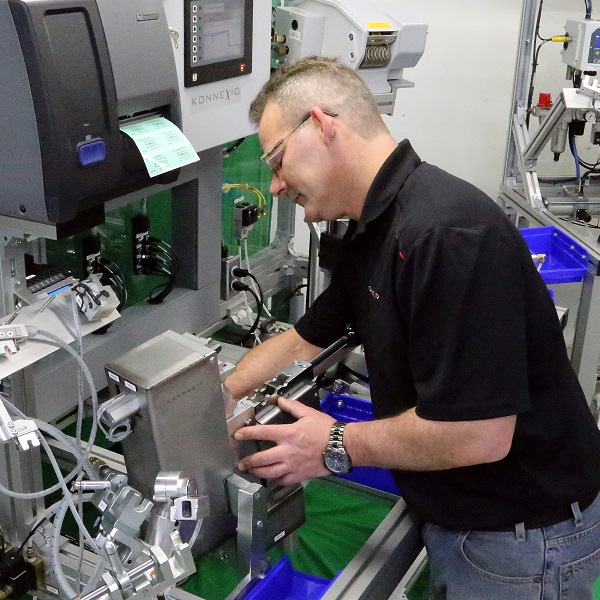

KONNEXIO’s team of highly skilled, expert designers and industrial mechanics work together to develop and build the most cost-effective and highly efficient solution which is unique to each customer’s project but at the same time, based on the adapto™ master concept.

From single station standalone applications, that are highly flexible and easily integrated into existing machines, to new and more elaborate fully-automatic systems, KONNEXIO’s adapto™ employs the most advanced technology to achieve superior results.

KONNEXIO’s on-site machine shop provides cost containment advantages through in-house, precision parts production. The result is a highly-reliable assembly machine with a shorter time-to-market, lower investment cost, easy future retooling alternatives, and responsive customer service.