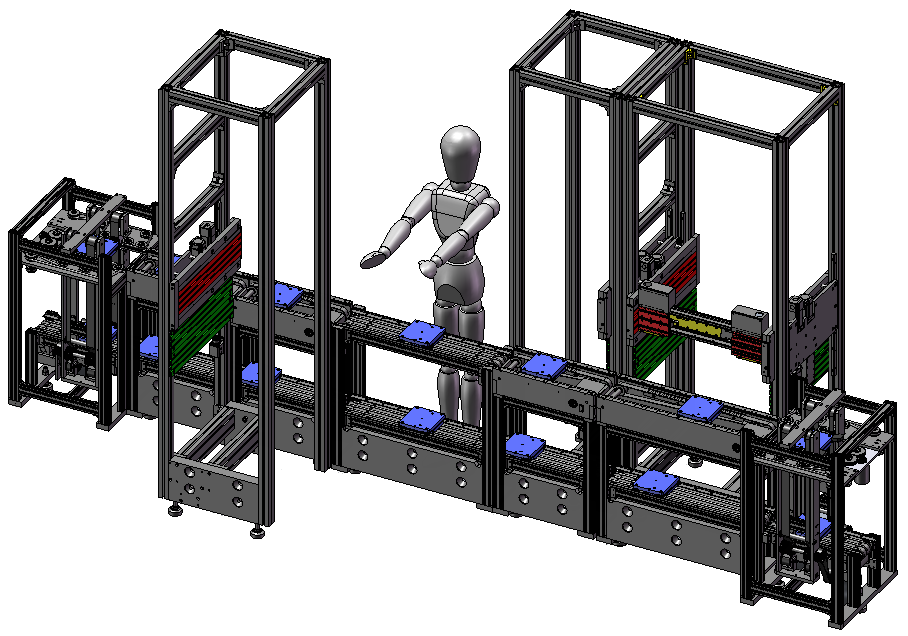

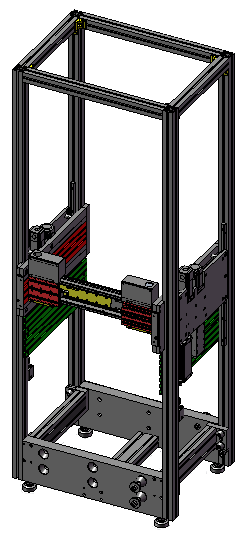

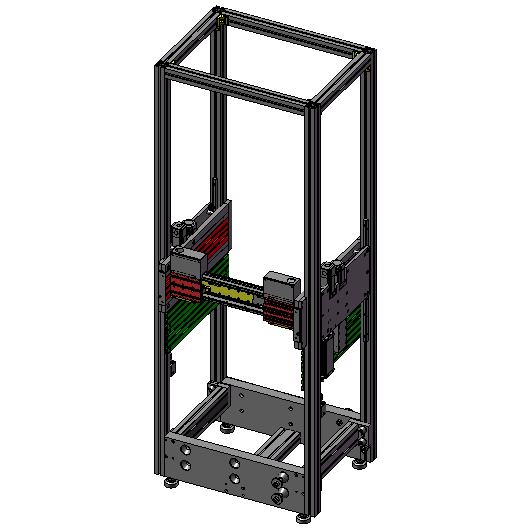

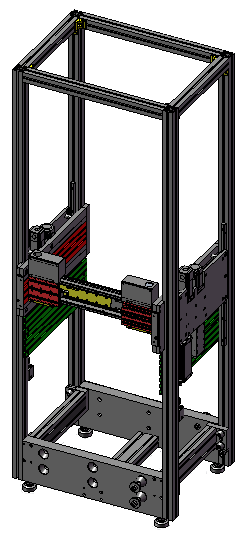

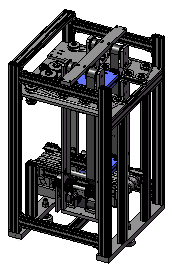

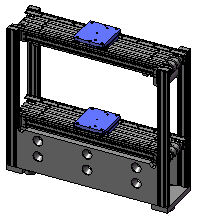

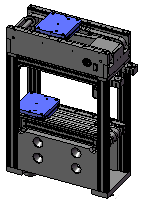

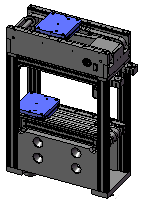

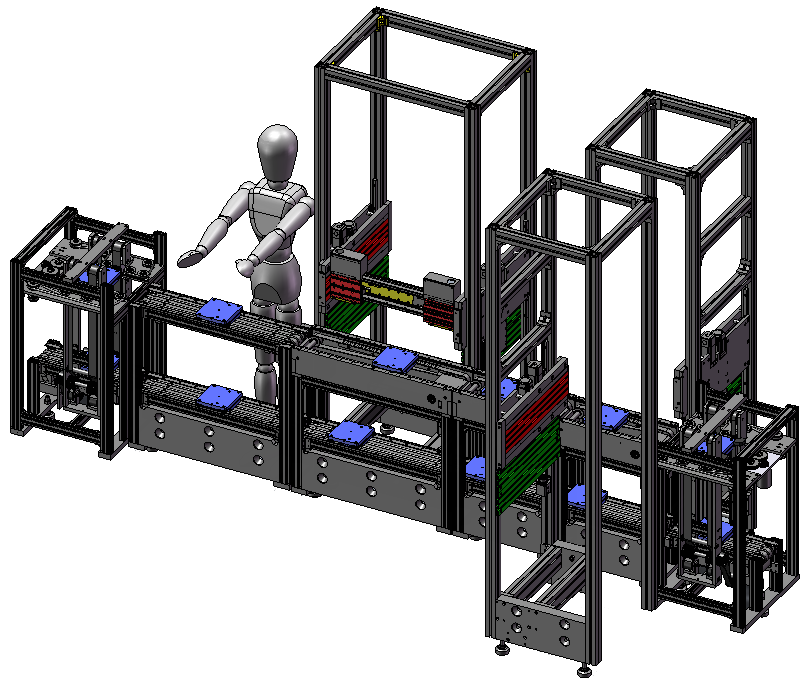

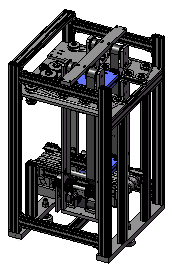

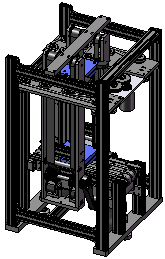

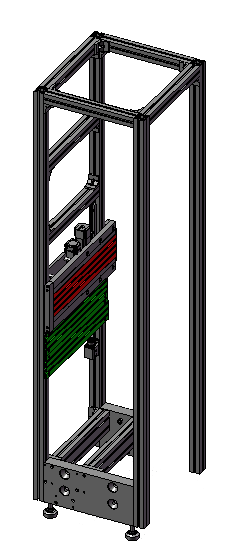

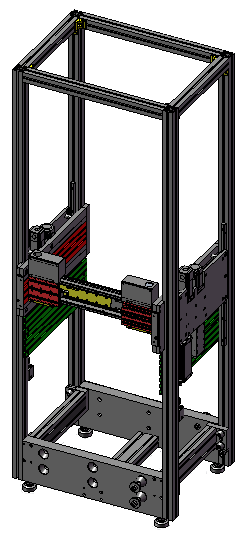

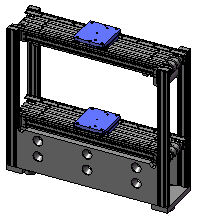

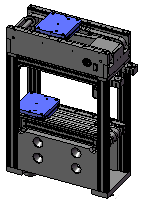

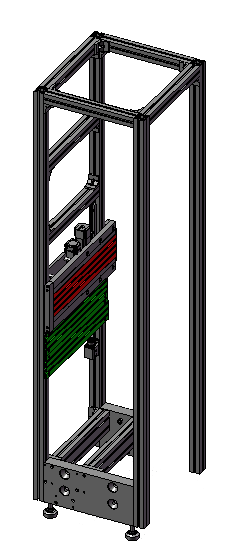

adapto™ is a unique and innovative assembly automation and testing machine system comprised of modular Smart Cells. These Smart Cells can be employed individually as stand-alone assembly and testing machines able to perform multiple operations or may further be linked together to create a highly complex assembly line performing any number of assembly and testing functions. A wide range of industry sectors, including Tier 1 and Tier 2 automotive parts assemblers, medical device manufacturers, transportation, and consumer goods manufacturers have gained the flexibility to quickly and inexpensively adjust tooling and processes in order to accommodate product modifications.

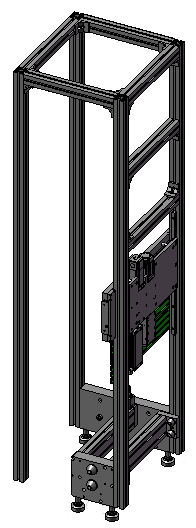

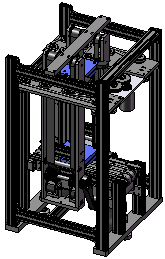

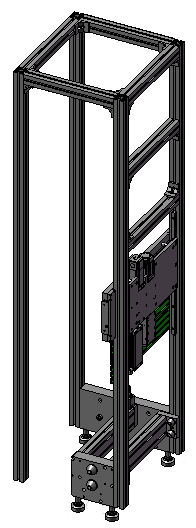

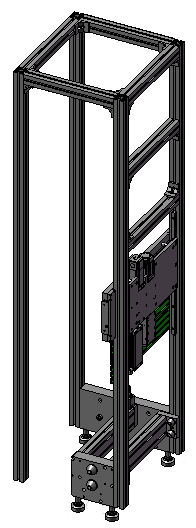

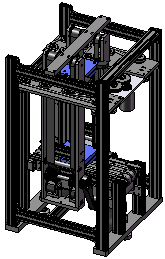

These individual Smart Cells, either semi or fully automatic, work independently as standalone machines but can be easily linked together or integrated into complex assembly sequences.

Scroll Down

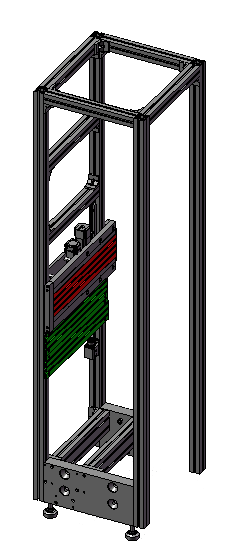

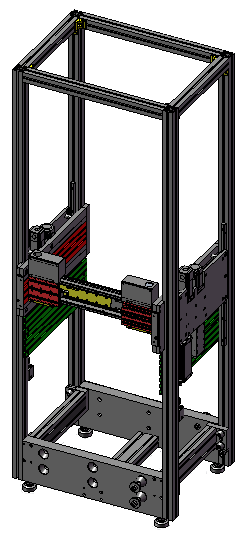

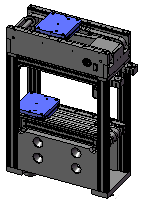

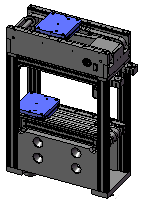

Add or remove processes from your assembly line in a fraction of the time.

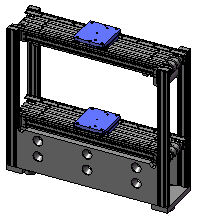

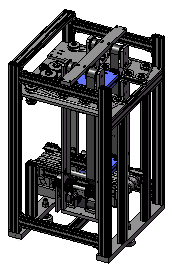

Peripherals such as vision systems, feeding systems, and robots are easily integrated as needed allowing implementation of the optimal level of automation at a given time.

Add custom tooling or generic pick-and-place machines.

Smart Cells allow completion of all facets of construction to be simultaneous with the customers product development in order to ensure a quicker time-to-market and ROI. Engineering changes are easily adapted and integrated because of the distinctive modular design.

Easily add to an existing process with limited downtime.