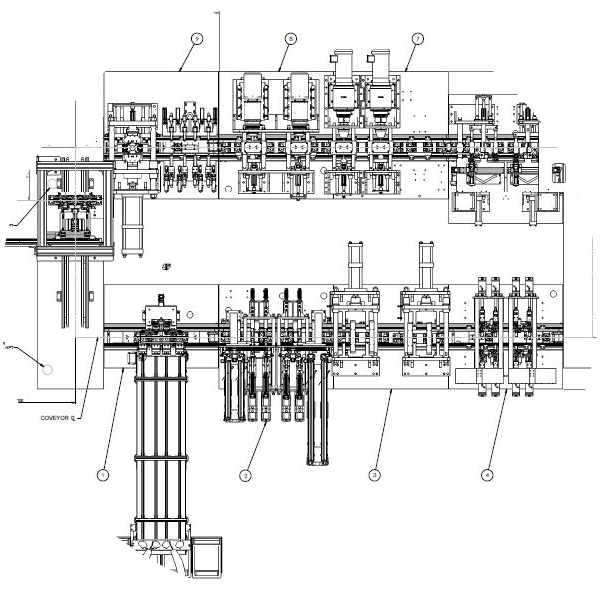

Case Study 312A

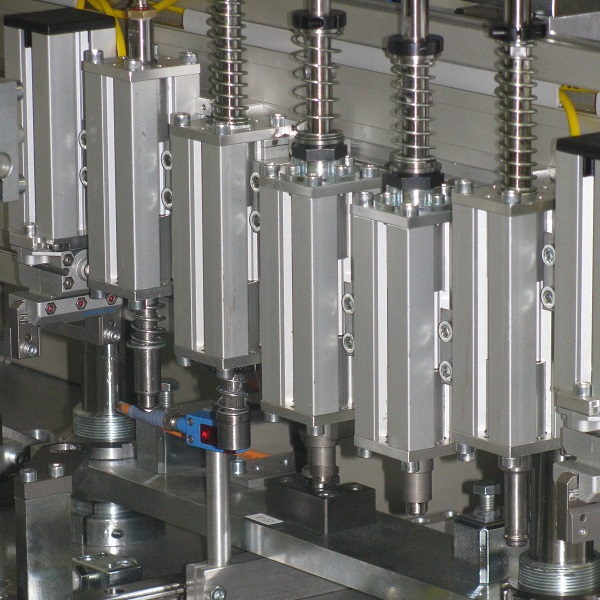

Automotive Hinge Assembly

Characteristics

- modular Smart Cells, completely controlled and operated within semi-automatic assembly line

- one semi-automatic parts loading station

- one manual parts loading station

- 8 fully automatic operating Smart Cells

- custom developed gantry robot for loading and unloading of punching press

- 12 second cycle time : 4-up assembly mode

- two parts variations with changover fixtures and tooling

Processes Integrated into Machine

- automatic parts feeding with vibratory bowl feeders and blow feeders

- pick-and-place and parts manipulation in 3D space

- air-over-oil press insertion, flaring, and staking operations

- orbital riveting

- LVDT parts measuring

- servo driven gantry robot covering four meter travel distance

Challenges & Accomplishments

- limited space requirement met

- performance requirement achieved

- gantry robot traveling long distances for loading and unloading parts into press

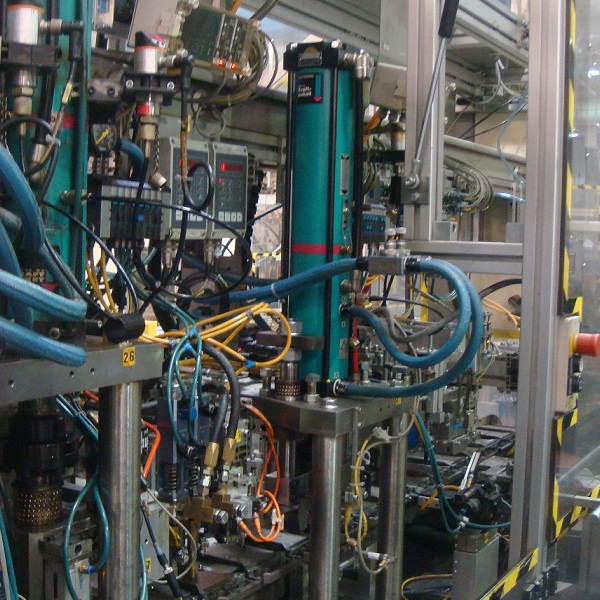

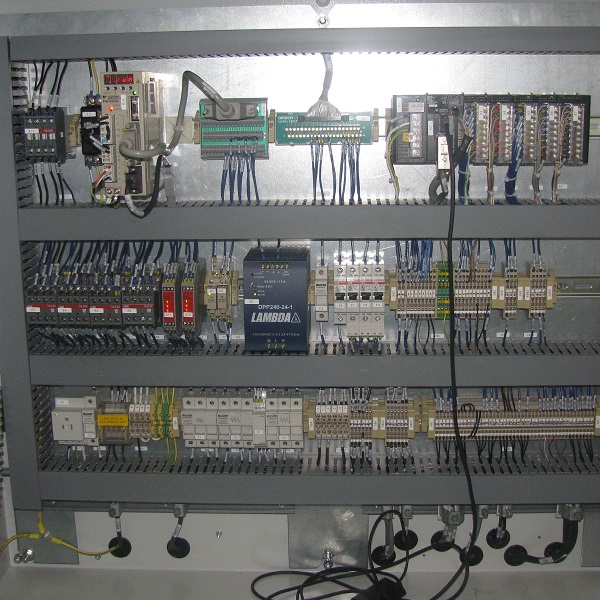

Case Study 12301/302

Automotive Door Checker Assembly

Characteristics

- cam driven linear indexing machine

- entirely sychronized motions via cam shaft

- two machines with 18 fully automatic stations

- high speed performance: up to 30 cycles per minute

Processes Integrated into Machine

- cam driven pick-and-place

- automatic parts feeding

- air-over-oil staking and crimping operations

- LVDT parts measuring

Challenges & Accomplishments

- durable, precise, high-performance machines

- in operation since 1995

- 4 very similar lines have since been built

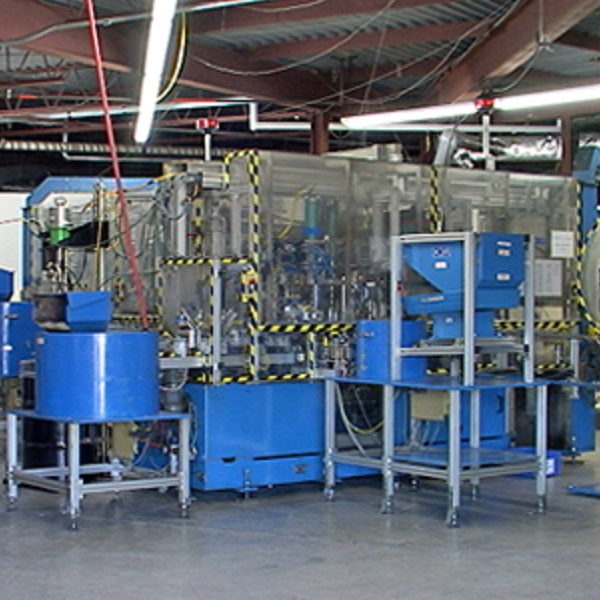

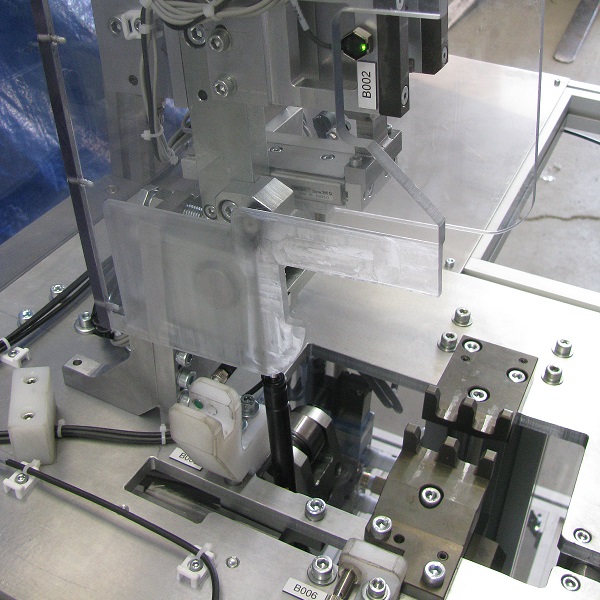

Case Study 314D

Automotive Fuel Line Assembly & Testing

Characteristics

- Height adjustable frame

- Easily accessible components

- Loading and unloading assists

Processes Integrated into Machine

- Leak testing

- Clip assembly

- Convolute and Mesh Sleeve checking

- Bracket folding and crimping tool

- Greasing operation with 90° swivel tools

Challenges & Accomplishments

- Tools developed for tight space constraints

- Ferrule checking integrated into leak test tools

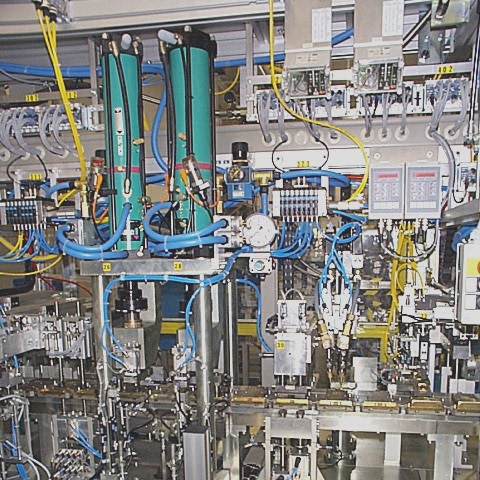

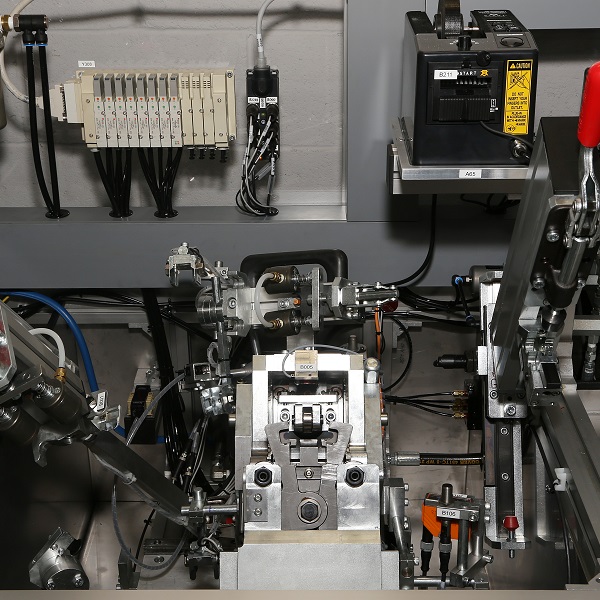

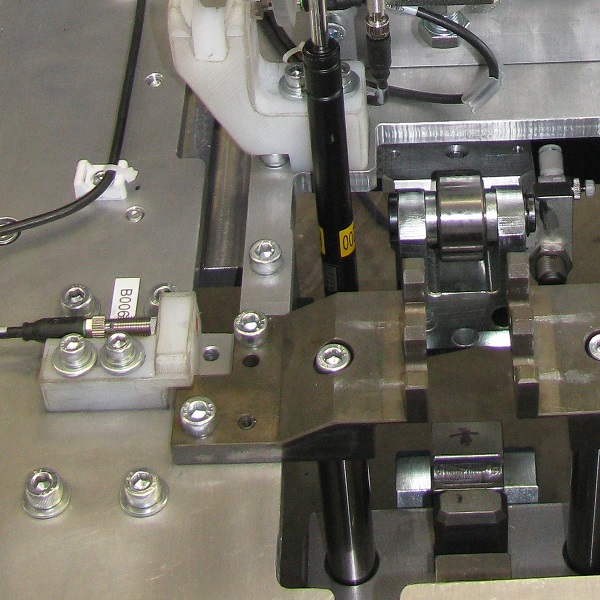

Case Study 308006

Automotive Plug Seal Assembly & Testing

Characteristics

- single station assembly machine

- manual parts loading

- automatic assembly and testing processes

Processes Integrated into Machine

- leak testing

- flow test with low pressure

- servo driven assembly motions

- vision inspection of all components

Challenges & Accomplishments

- only two pneumatic and one servo motion used for 7 processes

- highly efficient

- programmable and expandable

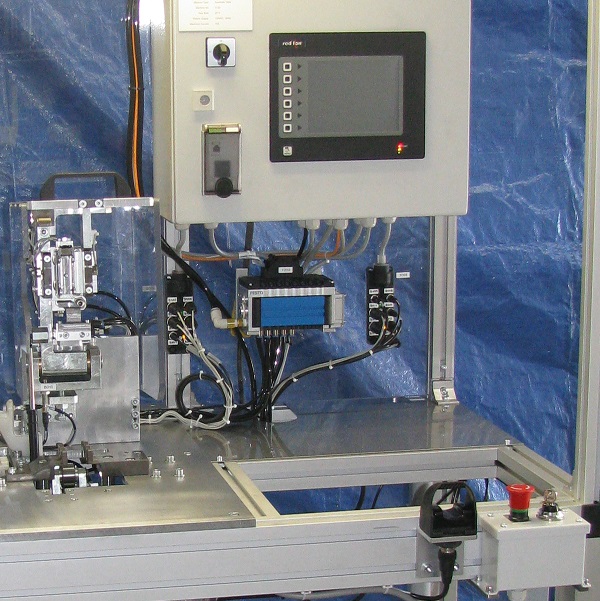

Case Study 313P

Automotive Fuel Line Assembly

Characteristics

- manually loaded assembly and testing cells

Processes Integrated into Machine

- leak testing

- bracket crimping

- various clip assembly and closing

- label printing and colour sensing

- convolute, sleeve & tape checking

- localized guarding

Challenges & Accomplishments

- 3D parts geometry

- tooling mounted adjustably in space to accommodate parts tolerences and deviations

- modular tooling design

- "future use" base machine concept: allows for easy upgrades and retooling

- "easy access" base machine system

Case Study 313D

Automotive Transmission Line Assembly

Characteristics

- manually loaded assembly and testing cells

Processes Integrated into Machine

- leak testing

- bracket crimping

- various clip assembly and closing

- label printing and colour sensing

- convolute, sleeves, tapes, and similar parts checking

- localized guarding (instead of light curtain) where possible

- verification of ferrule crimps

- pal nut assembly

- greasing application

- shipping cap assembly and checking

Challenges & Accomplishments

- ergonomic requirements due to 3D parts geometry

- tooling adjustability required for handling of several product variations

- modular tooling design

- "future use" base machine concept : allows for easy upgrading and retooling

- "easy access" base machine system

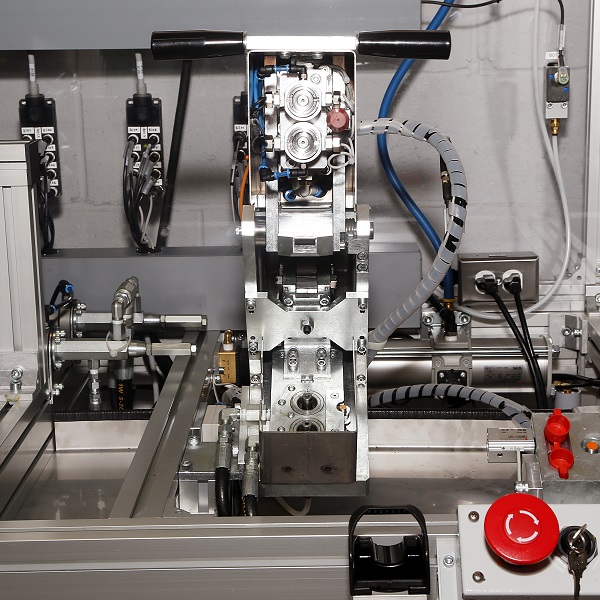

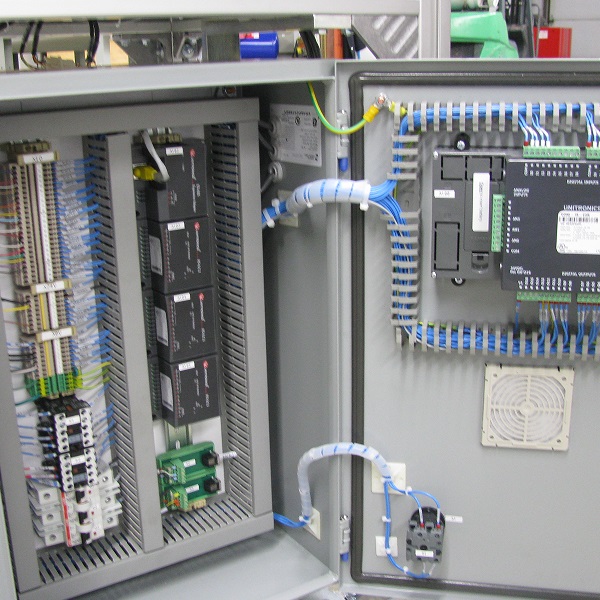

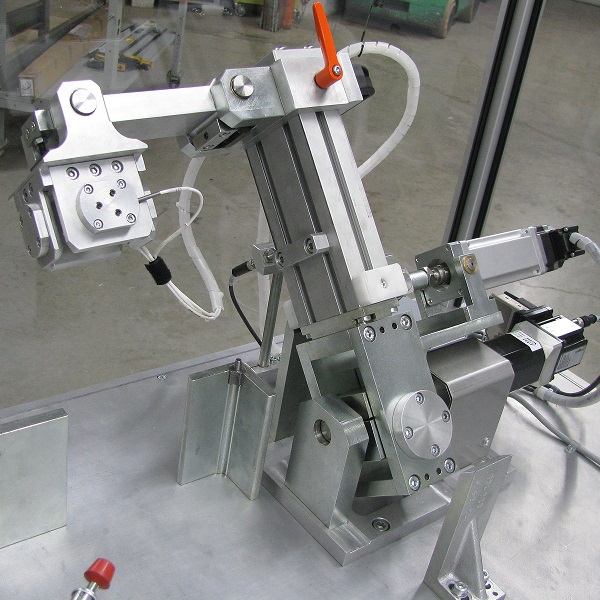

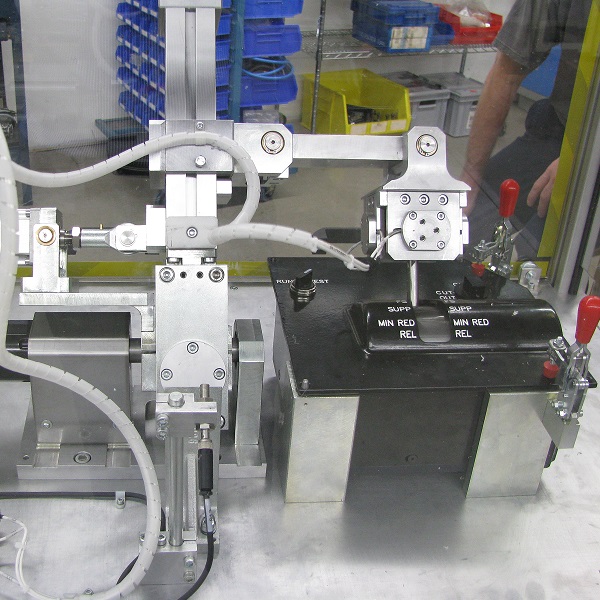

Case Study 311003

Locomotive Brake Handle Tester

Characteristics

- testing machine to measure forces of handle activation

Processes Integrated into Machine

- entirely servo driven (no pneumatics used)

- fully programmable

Challenges & Accomplishments

- all motions and processes required operation without use of pneumatics

- precise accuracy force measurement required

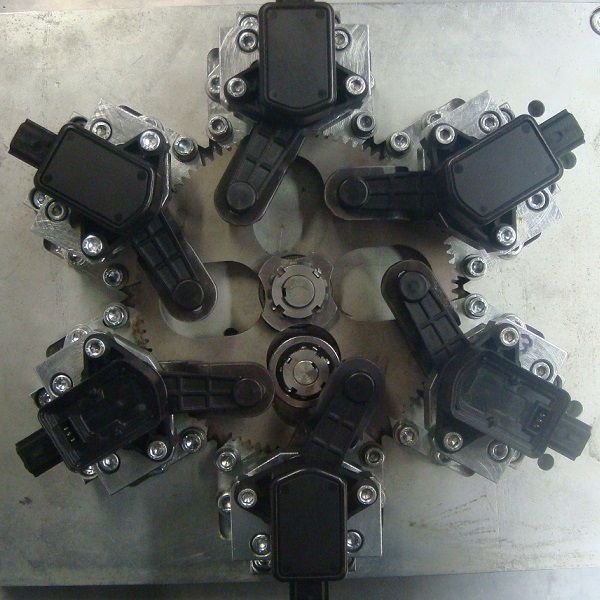

Case Study 313B

Hybrid Automotive Sensor Tester

Characteristics

- machine to test lifetime of automotive level sensor

Processes Integrated into Machine

- electric drive system with mechanical oscillator functions

Challenges & Accomplishments

- very high performance - cycle testing at 50 Hz (5o cycles per minute)

- overcoming high inertia in mechanical system at high speed

- drive and mechanical systems to withstand the product life cycle at high performance